漫反射是光线投射到粗糙表面上,发生方向反射的现象。当一束平行光线照射到一个粗糙表面上时,该表面会把光线向四面八方反射,因此入射线互相平行,而由于各点的法线方向不一致,导致反射光线向不同方向无规则地反射,这种现象就称为“漫反射”,反射出来的光就称为漫反射光,如下图所示:

漫反射彩涂铝板是利用光的漫反射原理,利用具有漫反射功能的涂料和特殊的辊涂工艺涂上一层涂层,结合纳米级微小粒子技术,在涂层表面形成微小的凹凸面,让照射到涂层表面的光线反射率达到95%以上的反射率。当光线在物体表面发生漫反射时,我们就可以从不同的角度看到物体表面。

联系我们1、产品优势:

2、漫反射彩涂铝板性能参数:

| 序号 | 检测项目 | 国家标准要求 | 检测结果 | 检测依据 |

| 1 | 色差 | △E≤2.0 | 高于国标 | GB/T22412 |

| 2 | 光泽度 | 偏差≤10 | 高于国标 | GB/T22412 |

| 3 | 涂层厚度 | ≥120μm | ≥120μm | GB/T22412 |

| 4 | 铅笔硬度 | ≥HB | ≥HB | GB/T22412 |

| 5 | 柔韧性 | ≤3T | ≤2T | GB/T22412 |

| 6 | 附着力/级 | 划圈法 | 1 | GB/T22412 |

| 划格法 | 0 | |||

| 7 | 耐冲击性 | ≥20kg.cm | ≥20kg.cm | GB/T22412 |

| 8 | 耐沸水 | 2h无变化 | 2h无变化 | GB/T22412 |

| 9 | 耐溶剂性 | 200次不漏底 | ≥200次 | GB/T22412 |

| 10 | 耐盐酸性 | 2%HCL24h | 无变化 | GB/T22412 |

| 11 | 耐碱性 | 饱和Ca(OH)₂24 h无变化 | 无变化 | GB/T22412 |

| 12 | 耐油性 | 20#机油24h无变化 | 无变化 | GB/T22412 |

| 13 | 耐盐雾性(720h) | ≤1级 | 无变化 | GB/T22412 |

| 14 | 耐沾污性 | ≤5% | 高于国标 | GB/T22412 |

| 15 | 耐人工气候老化性 (老化时间600h) |

色差△E≤2.0 | △E≤2.0 | GB/T22412 |

| 失光率/级≤2 | ≤2 | GB/T22412 | ||

| 其它老化性能0级 | 0级 | GB/T22412 | ||

| 16 | 可见光反射率 | ≥95% | 高于国标 | GB/T11186.2-2004 |

| 17 | 550mm反射率 | ≥95% | 高于国标 | GB/T11186.2-2004 |

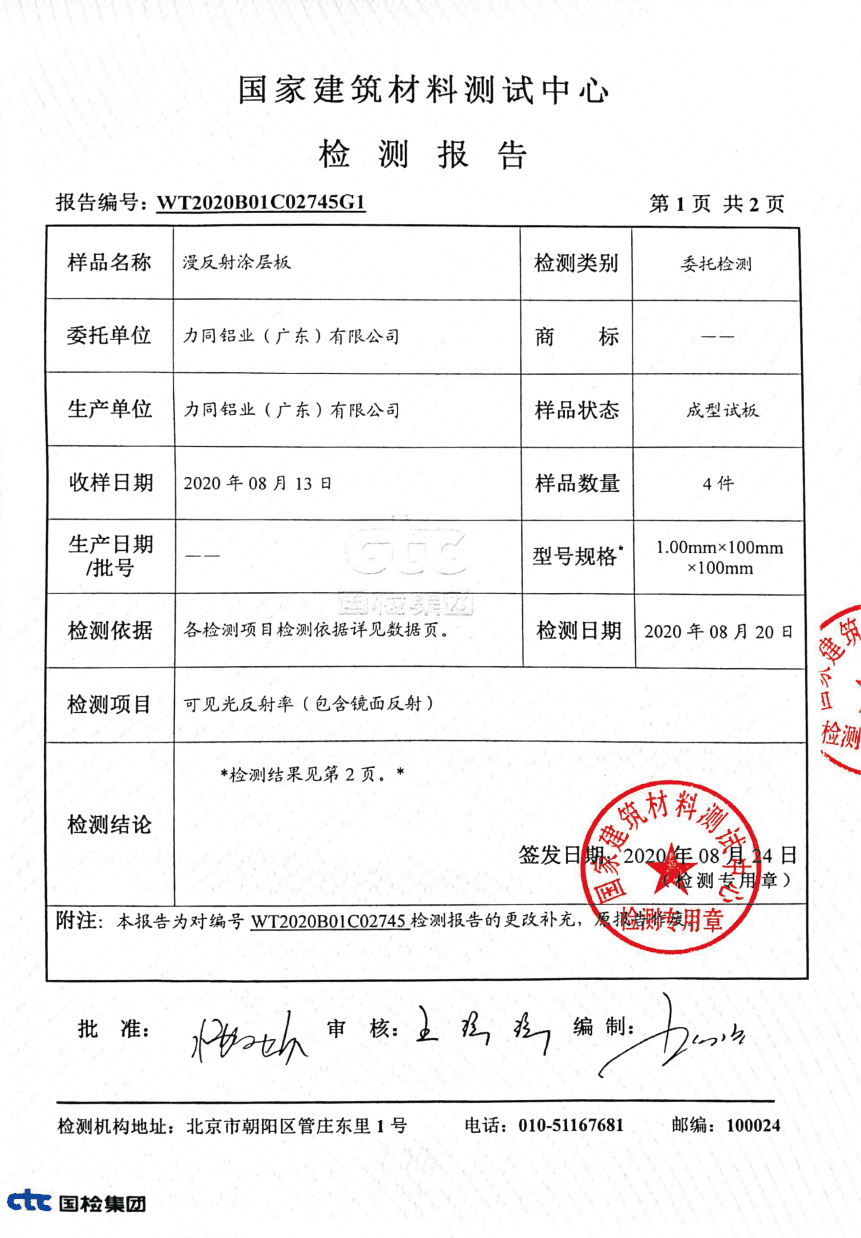

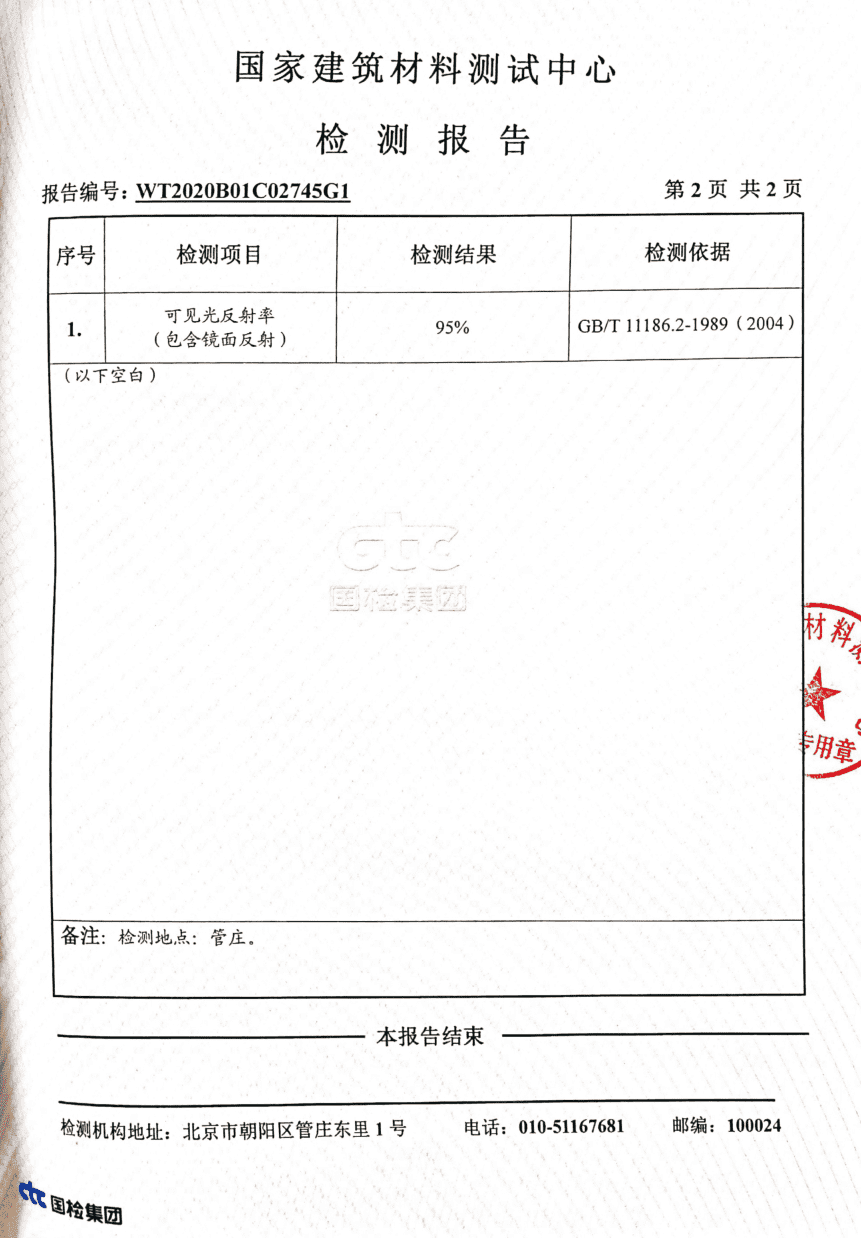

3. 检测报告

4、漫反射彩涂铝板的规格型号:

5、漫反射彩涂铝板应用领域:

6、典型工程案例: