铝锥心复合板创意来源于中国古代的孔桥(拱桥)的建筑力学和美学,通过水平推力把原本由载荷产⽣的弯矩应力变成压应力或⼤部分转化成压应力,使拱的弯矩大大减少,拱主要承受压力,充分发挥铝合金材料的抗压能力。彩涂铝板在铝锥心板的发展过程中起到极其重要的作⽤,出色的铝合金性能,绚丽多彩的颜色选择,A级防火性能,环保以及零甲醛的涂层性能,大大促进了铝锥心板的发展。

联系我们1.铝锥心板基材的产品特点:

2、铝锥心板基材的规格型号:

3. 检测报告

4.应用领域:

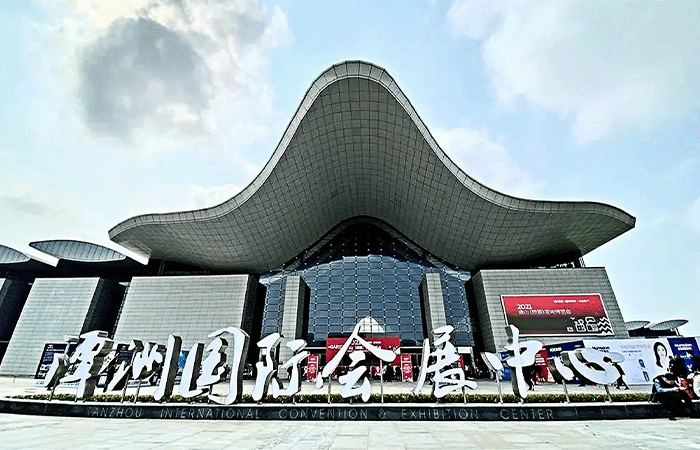

5.应用案例

广东潭洲国际会展中心

湖北省武汉市江夏区法院办公楼

湖北省妇幼发展中心