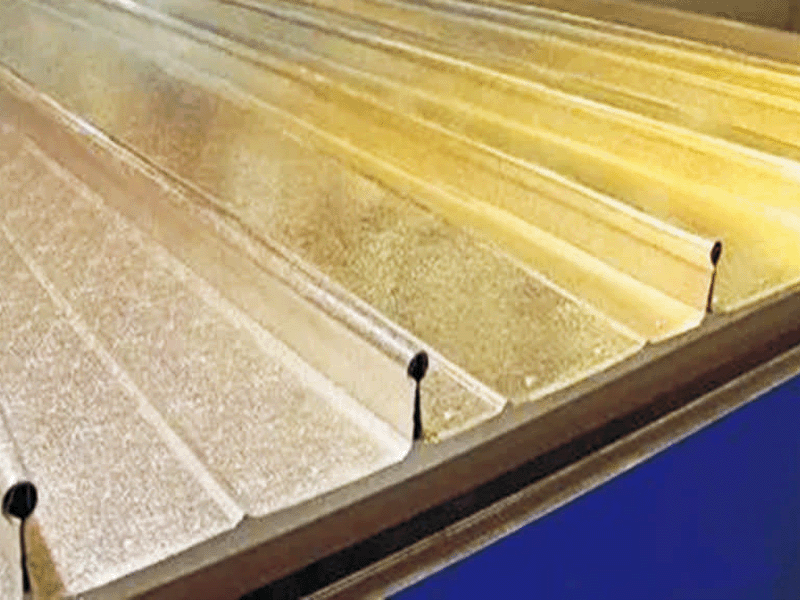

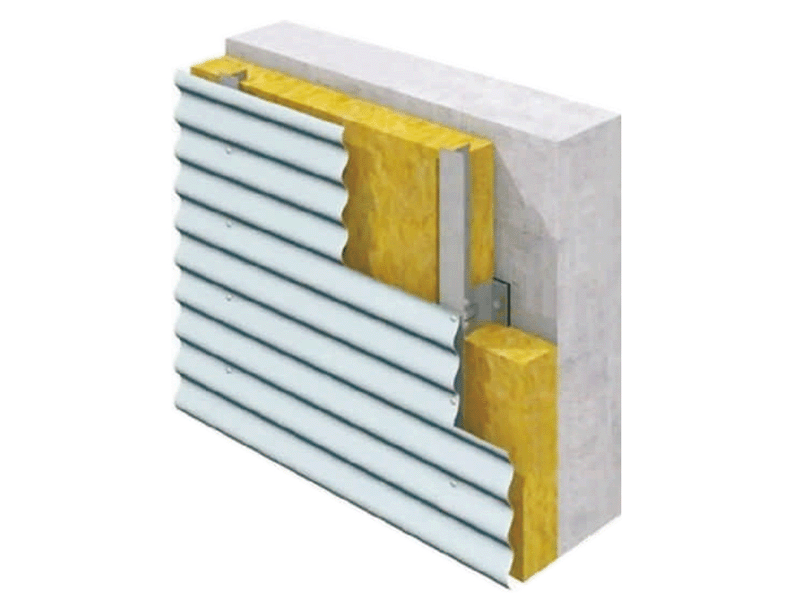

铝镁锰合金彩涂铝板的铝合金基体中含有一定比例的金属镁和锰,以增加铝合金的强度和加工性能。其表面处理通常采用辊涂方式涂覆耐候性好的氟碳(PVDF)涂层。铝镁锰彩涂铝板主要用于金属屋面、墙面系统。

联系我们1、铝镁锰板屋面、墙面实景图片:

2、铝镁锰彩涂铝板特点:

3、彩涂铝镁锰板屋面与彩钢板屋面对比优势:

| 类别项目 | 彩涂铝镁锰板的特点 | 彩钢板的特点 |

| 耐用性 | ★与大气形成一层氧化铝薄膜,防止进一步腐蚀。 ★50使用寿命一年以上。 |

★在潮湿空气、雨雪的侵蚀下,容易腐蚀生锈,特别是接缝处。 ★不超过10年的使用寿命。 |

| 重量 | ★自重轻(密度为2700kg/m³),钢结构承重小,可减少钢结构用量。 ★使建筑物所承受的重量负荷减至最低。 |

重量比较重(密度为7850kg/m³),钢结构承重能力强,用量也相应较大。 |

| 强度和刚度 | ★铝合金中含有镁、锰等元素,具有一定的强度和刚度。 ★可抵御严寒、酷热、地震、暴雨、冰雹、火灾等。 ★最高抗风能力120mph(哩/小时)。 |

★强度、刚度好。 ★可耐严寒、防火、地震、暴雨、冰雹、火灾等。 |

| 防雷性能 | 厚度一般为0.7mm、0.9mm,可直接作为避雷器使用(国标< |

一般采用0.5mm厚的镀铝锌、镀锌钢板,不能直接作为避雷器使用,必须加装单独的避雷装置(如避雷针)。 |

| 防火等级 | A级,不燃烧。 | A级,不燃。 |

|

资源环保回收利⽤

|

可回收再利用,残余价值⾼ | 不可回收再利用,基本无残余价值 |

4、铝镁锰彩涂铝板规格:

★ 合金状态:3004H24、3104H24、5754H24等含镁、锰铝合金;

★ 基材厚度:0.5mm-1.5mm;

★ 基材宽度:常见规格有600mm、575mm、578mm、500mm等,可根据客户需求定制。

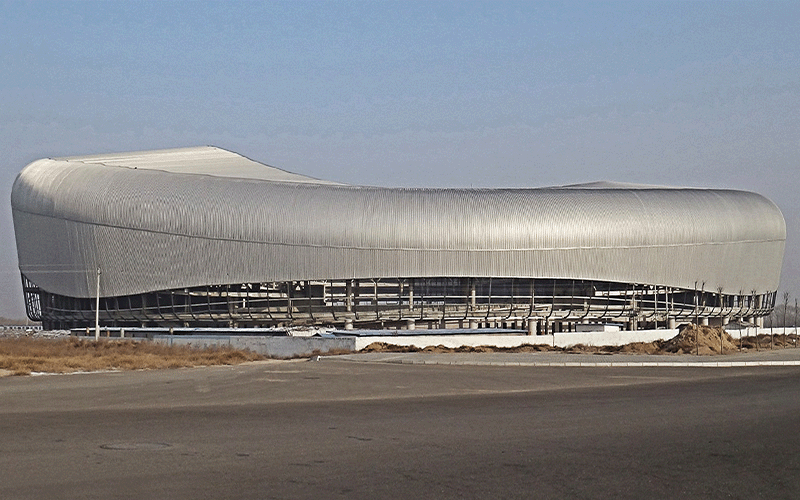

5.应用领域:

广泛应用于机场、车站、展览中心、体育馆、大型公共建筑、大型工厂等建筑的屋面围护系统、墙体系统。

6.应用案例:

京都世界园艺博览会主题馆

郴州国际会展中心

西宁曹家堡国际机场

鄂尔多斯市准格尔旗体育馆

广州花都体育中心

苏州桑天岛生物产业园